Technologies

ElectroMagnetic Acoustic Transformation (EMAT)

Provides an opportunity for non-contact excitation of various acoustic waves with different polarizations in the tested object. Modern hardware base enables production of flaw detectors and thickness gauges that implement EMAT and operate with operating clearances of up to 10 mm. This means that there could be paint, plastic, dirt, air and other non-conductive media, thickness up to 10 mm, between the surfaces of tested objects and the sensor surface.

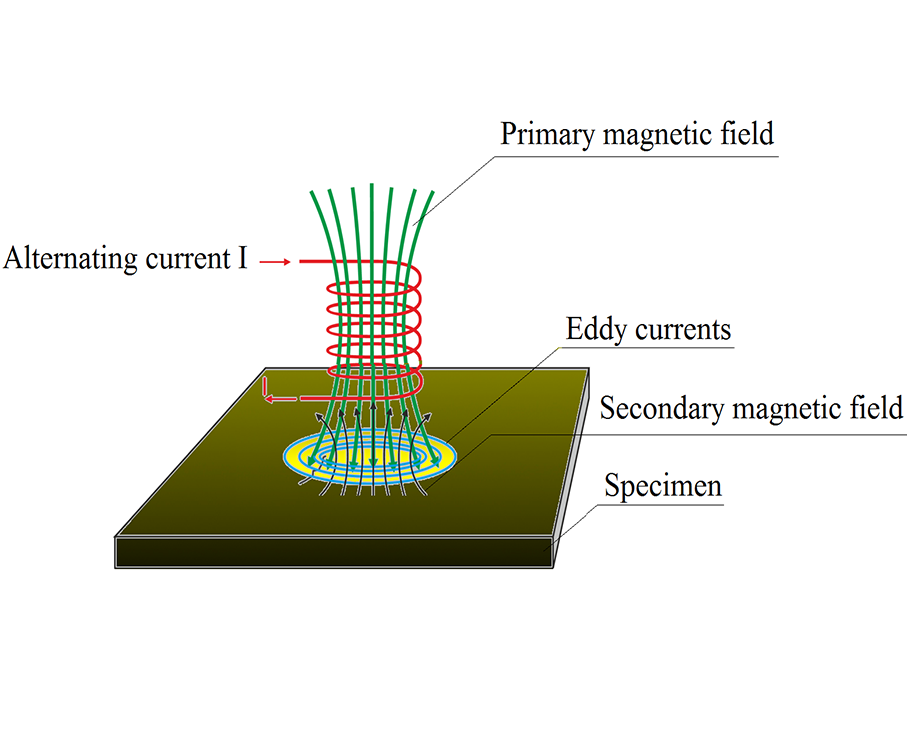

More…Eddy Current Non-destructive Testing

The eddy current non-destructive method allows non-contact and quick diagnostics of metal objects. Modern devices that use the eddy current method can: detect and evaluate sizes of surface and subsurface defects, detect in certain conditions the defects existing on the tested object’s internal surface, measure the distance between the sensor and tested object, measure the thickness of tested objects particularly objects made from steel.

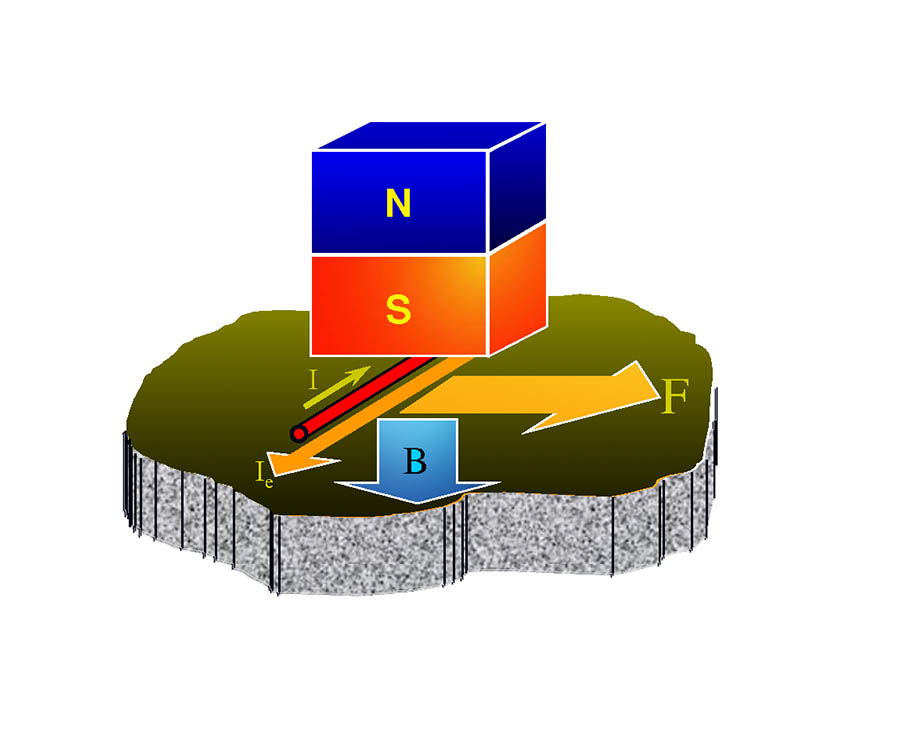

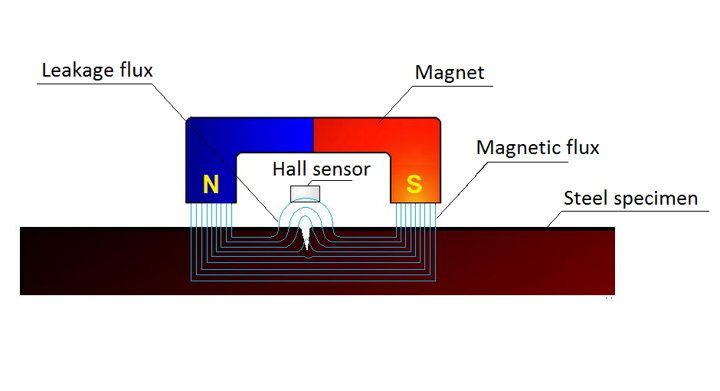

Magnetic Test Method

The magnetic test method relies on the analysis of stray fields that emerge in the course of tested object magnetization in defect areas. The method enables high-performance express diagnostics of the condition of ferromagnetic tested objects. The method is used in the diagnostics of pipes with narrow and wide diameters, particularly in magnetic swabs for main pipe tests. It is used for testing vertical steel tanks, in industrial rod and rolled sheet tests. This is a non-contact method, and it requires no surface preparation.

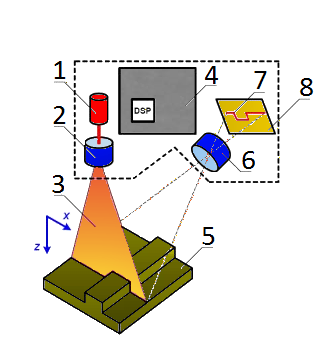

More…Laser Profilometry

The laser profilometry method allows detecting surface defects on tested objects and also making accurate measurements of geometric dimensions of defects. This is a non-contact method. The distance between the optical system and the tested object’s surface can reach several tens of centimeters. In particular, the method can be used for automated quality control of surface defects in weld joints.

More…