Price on request

Description

Oktanta designs and manufactures systems and devices for non-destructive testing according to the technical requirements provided by customers. We use all the existing test methods, including EMAT (non-contact ultrasound excitation), eddy current testing and magnetic non-destructive testing (MFL).

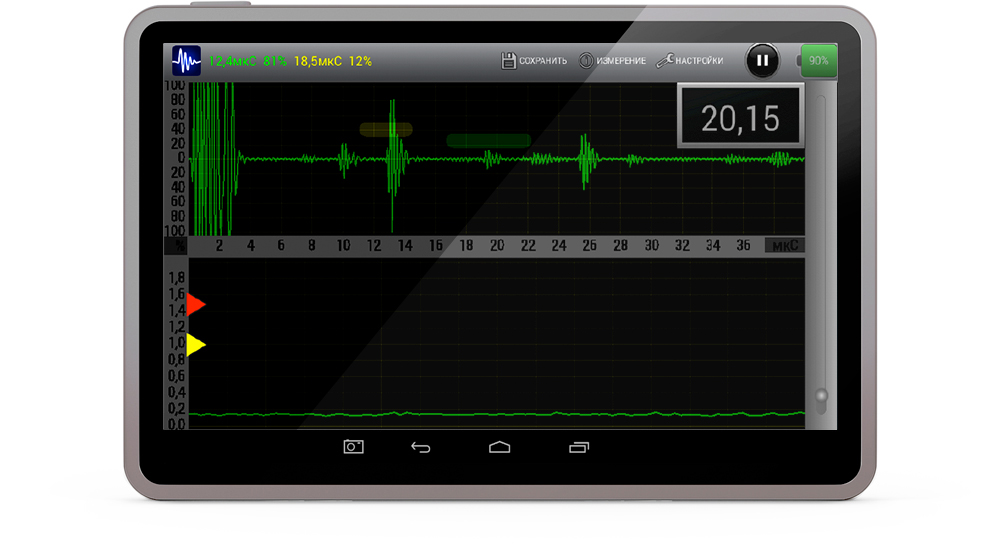

EM2020 is a mountable EMA module with a transducer and software. It is a system that uses EMAT for thickness measurement and flaw detection on steel sheets, steel pipes, products made from aluminum and other metals.

EMA transducers can be supplied as: EMAT with direct acoustic wave input, EMAT with inclined acoustic wave input, EMAT with generation and receipt of Rayleigh surface waves, EMAT with generation of head waves, EMAT with generation and receipt of standard acoustic waves (Lamb waves).

Available interfaces to connect a PC and unit: USB, RS422/RS485, CAN, Ethernet, WiFi, RF 433 MHz/866 MHz, GSM. As regards software, available options include our Windows software and software developed according to the technical requirements provided by a customer, both Windows and other operating systems, e.g. Android OS. Software allows displaying information on the A, B and C scans (the B and C scans require information about the sensor’s position), working with strobes, implements various digital filters, including matched filtering for accurate echo signal positioning, coherent accumulations to increase the signal-noise ratio, implements various screening mechanisms.

Technical specifications of the EM2020 thickness gauge

| Range of measured thicknesses | 0 mm-100 mm |

| Thickness measurement error | 0,04 mm |

| Range of input angle for lateral waves in a steel tested object | 0..4, 25..40 |

| Available type of lateral wave polarization | Wave with vertical polarization, wave with horizontal polarization, wave with radial polarization |

| Type of excited waves | Steel: SH,SV, Rayleigh, Lamb Non-magnetic metals: L,SH,SV, Rayleigh, Lamb |

| Range of input angle for lateral waves in a non-magnetic metal tested object | 0..4, 25..45 |

| Range of input angle for a longitudinal wave in a non-magnetic metal tested object | 0..4 |

| Frequency range | 100 kHz…10 MHz |

| Power consumption | 3 W to 40 W depending on the relative pulse duration |

| Highest number of measurements per second | 50 |

| Power supply voltage | As requested by a customer |

| Operating temperature range | -20…+50 |

| Dimensions | 170 x 100 x 40 mm, Can be changed as requested by a customer |