Description

The EM1401 EMA thickness gauge is designed for thickness measurement on steel pipes, sheet metal, rods, and other products made from steel, aluminum and other metals. The device can be connected to the EMAT with the operating clearance of up to 6 mm between the sensor and metal. The clearance can consist of dirt, layer of rust, layer of salt deposits or other non-conductive coating (paint, varnish, enamel, plastic, etc.). The device can connect to conventional PETs.

The EM1401 UT thickness gauge can connect to the EMT14014T high-temperature sensor that provides thickness measurement on hot objects heated up to 750 °C. The device implements a special algorithm that accounts for changes in the rate of sound propagation in metal induced by temperature.

Using the device:

Two independent EMAT and PET measuring channels provide an increase in reliability of tests. PET is recommended on the objects where the thickness of deposits existing on the metal surface prevents the use of EMAT and surface cleaning is required.

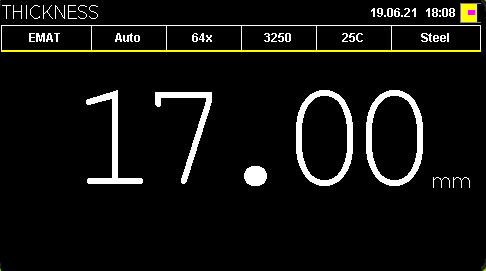

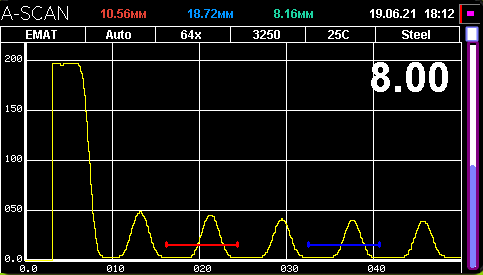

The EM1401 UT thickness gauge has a color display protected by shock-resistant glass. Like any other EMA thickness gauge produced by our company, the EM1401 UT thickness gauge uses a special data processing algorithm that provides automated correct thickness measurements in the presence of disturbing factors such as metal anisotropy, usage of several reflectors, exposure to external interference. In addition to the automatic mode of thickness measurement, the device allows using manual measurement modes based on the first echo and difference between any two echoes. Manual mode is recommended for severely corroded objects.

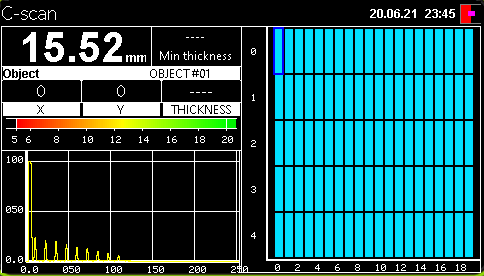

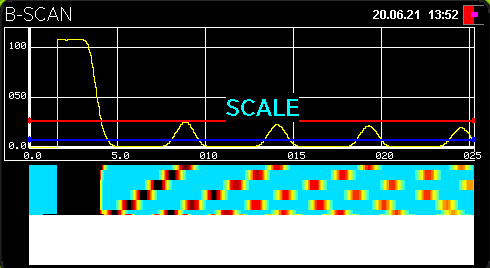

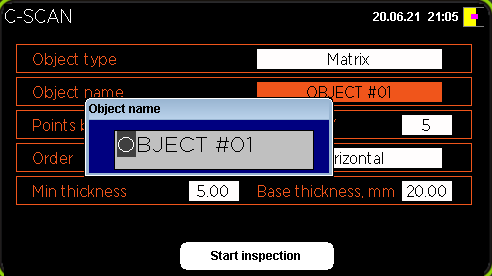

The EM1401 electromagnetic acoustic thickness gauge allows the user to analyze A-scans, visualize B-scans (three display options), and save data conveniently on C-scans in a matrix form. If necessary, the user can work with strobes, select a thickness measurement mode, signal processing parameters, etc.

| Range of operating ambient temperature | -20…+50 °С |

| Duration of continuous work without recharge of the battery |

7 hours |

| Range of sound velocity setting | 1,000…20,000 m/s with 1 m/s step |

| Highest number of measurements per second | 16 |

| Dimensions | 232 x 135 x 44 mm |

| For EMAT | |

| Range of measured thickness for steel | 2 mm-80 mm |

| Range of measured thickness for steel without clearance | 2 mm-200 mm |

| Thickness measurement error 2..25 mm | 0.08+0.001·Н mm |

| Thickness measurement error 25..200 mm | 0.1+0.005·Н mm |

| Permissible clearance between the sensor and tested object with the EMT14012 transducer |

Up to 4 mm |

| Permissible clearance between the sensor and tested object with The EMT14013 transducer |

Up to 6 mm |

| Permissible sensor skew relative to the tested object surface normal |

±25° |

| Lowest permissible radius of curvature of the tested object surface | ≥10 mm |

| Operating frequency of the device | 4 MHz |

| Range of operating temperature on the tested object surface | -20…+80 °C (-20 …+750 °C where the EMT14014T transducer is used) |

| For PET | |

| Range of measured thickness for steel | 0.5 mm-300 mm |

| Thickness measurement error 0.5mm .. 25mm | 0.08 mm |

| Thickness measurement error 25mm .. 300mm | 0.1 mm |

| Lowest permissible radius of curvature of the tested object surface | 25 mm |

| Operating frequency of the device | 5 MHz, 10 MHz |

| Range of operating temperature on the tested object surface | -10…+60 °C |