Description

The EM4000 EMA thickness gauge is designed for thickness measurement on steel pipes, sheet metal, rods, and other products made from steel, aluminum and other metals, with a operating gap of up to 3 mm between the sensor and metal. Operation of the EMA thickness gauge requires no preliminary surface preparation, no couplant is required. The gap can consist of dirt, layer of rust, layer of salt deposits or other non-conductive coating (paint, varnish, enamel, plastic, etc.). In addition to measuring metal thickness, the EM4000 allows measuring the thickness of non-conductive coating on metal.

Using the device:

A special sensor allows using the EM4000 thickness gauge for thickness measurements on objects heated up to 750 °C. Skew makes a minor effect on the device’s readings, in contrast to conventional thickness gauges with piezoelectric transducers that require sensor fixed in a certain position. The EM4000 thickness gauge has a color display protected by shock-resistant glass. The device uses a special data processing algorithm that provides correct thickness measurements in the presence of disturbing factors such as metal anisotropy, usage of several reflectors, exposure to external interference. The algorithm developed by our experts allows reducing the human factor and simplifying the device interface.

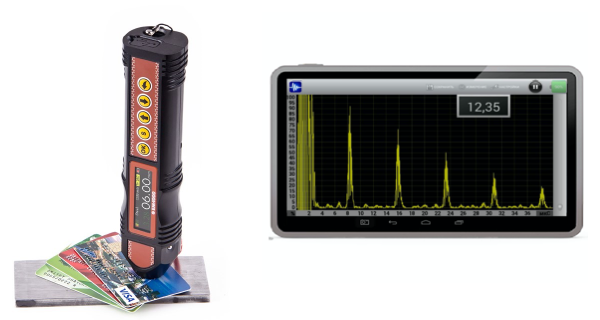

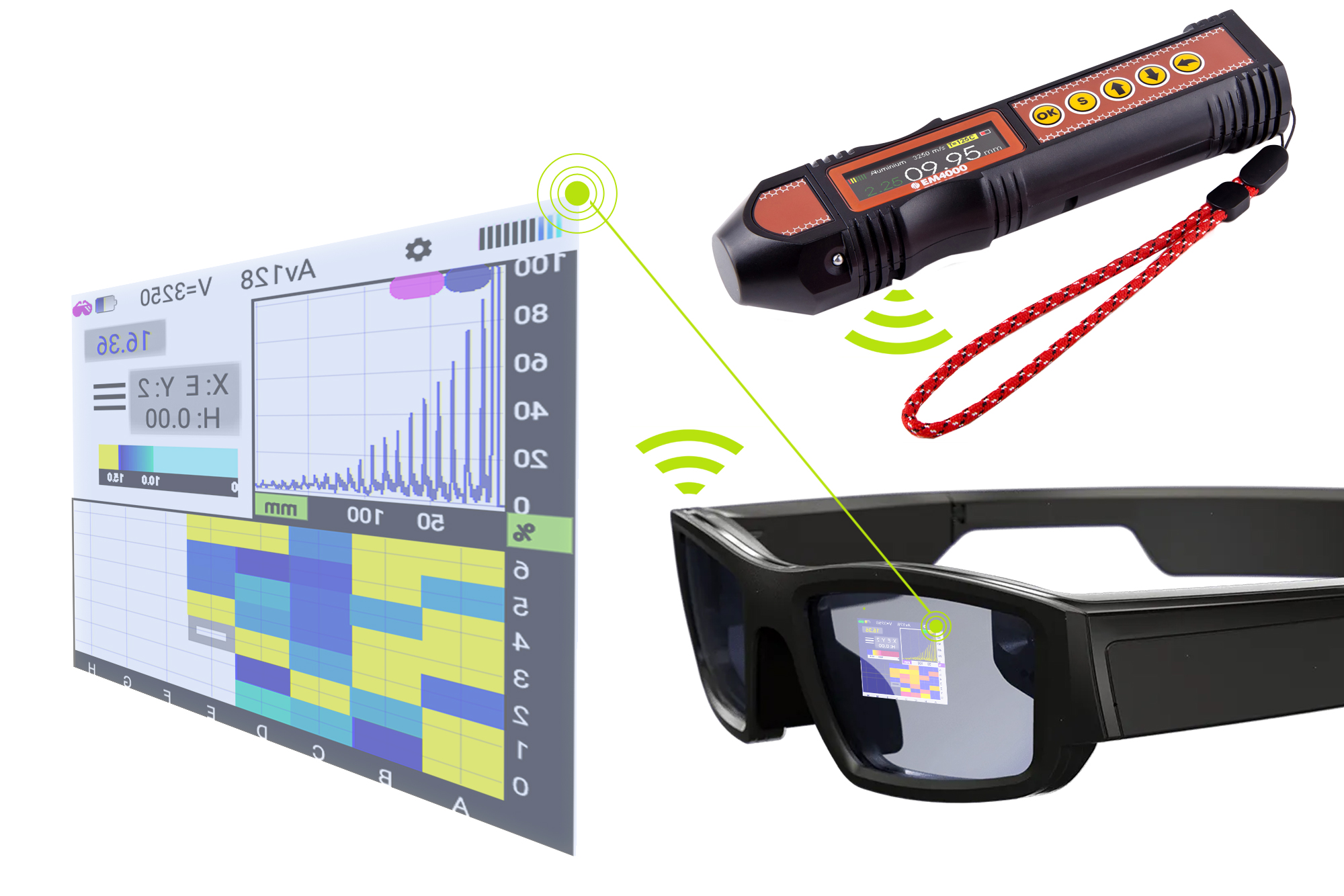

The EM4000 electromagnetic acoustic thickness gauge is capable of connecting to a tablet, smartphone or another device based on the Android OS. This allows expanding the thickness gauge features, analyzing A-scans, B-scans, working with strobes, selecting a thickness measurement mode, signal processing parameters, etc. The EMA thickness gauge can be connected to a tablet either wirelessly via Bluetooth

At your request, the EMA thickness gauge EM4000 can be supplemented with wearable smart glasses. Wearable smart glasses allow you to measure EMA with the EM4000 thickness gauge in hard-to-reach places where reading the device’s readings from the display is not possible or difficult. In this case, the readings are displayed on the glass of the smart phone.

glasses and are always visible to the operator.

EM4000 technical specifications

| Range of measured thickness for steel | 2..80 mm |

| Range of measured thickness for steel without gap | 2..200 mm |

| Thickness measurement error 2..25 mm | 0.08+0.001·H mm |

| Thickness measurement error 25..200 mm | 0.1+0.005·H mm |

| Permissible gap between the sensor and tested object | up to 3 mm |

| Range of measured thicknesses in non-conductive coatings | 0…4 mm |

| Measurement error for non-conductive coating thickness | 0.1 mm ±3% |

| Permissible sensor skew relative to the tested object surface normal | ± 25° |

| Lowest permissible radius of curvature of the tested object surface | ≥10 mm |

| Highest number of measurements per second | 4 |

| Range of sound velocity setting | 1000…9999 m/s with 1 m/s step |

| Operating frequency of the device | 4 MHz |

| Duration of continuous work without battery recharge | 7 hours |

| Range of operating ambient temperature | -20…+50 °C |

| Range of operating temperature on the tested object surface | -20…+80 °C (-20 …+750 °C where the EMT40004T transducer is used) |

| Dimensions | 185 x 43 x 35 mm |