Приборы и системы бесконтактного контроля

Контроль труб городских теплосетей

Наша компания оказывает услуги по внутритрубной диагностике диагностическим комплексом HeatScan. Применяемая технология позволяет контролировать состояние металла через слой отложений до 35 мм и оценивать остаточный ресурс дефектных участков

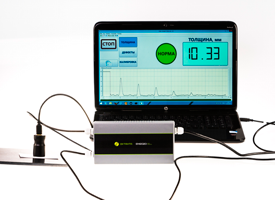

Встраиваемые системы неразрушающего контроля

Компания Октанта разрабатывает и изготавливает системы и приборы неразрушающего контроля по техническим требованиям заказчика. Основные наши направления это ЭМА дефектоскопия и вихретоковый неразрушающий контроль

Консалтинг в сфере неразрушающего контроля

Консультации и аналитика в вопросах проведения неразрушающего контроля и экспертизы промышленной безопасности. Аудит лабораторий НК.