Description

The eddy current non-destructive method allows non-contact and quick diagnostics of metal objects. Modern devices that use the eddy current method can: detect and evaluate sizes of surface and subsurface defects, detect in certain conditions the defects existing on the tested object’s internal surface, measure the distance between the sensor and tested object, measure the thickness of tested objects particularly objects made from steel.

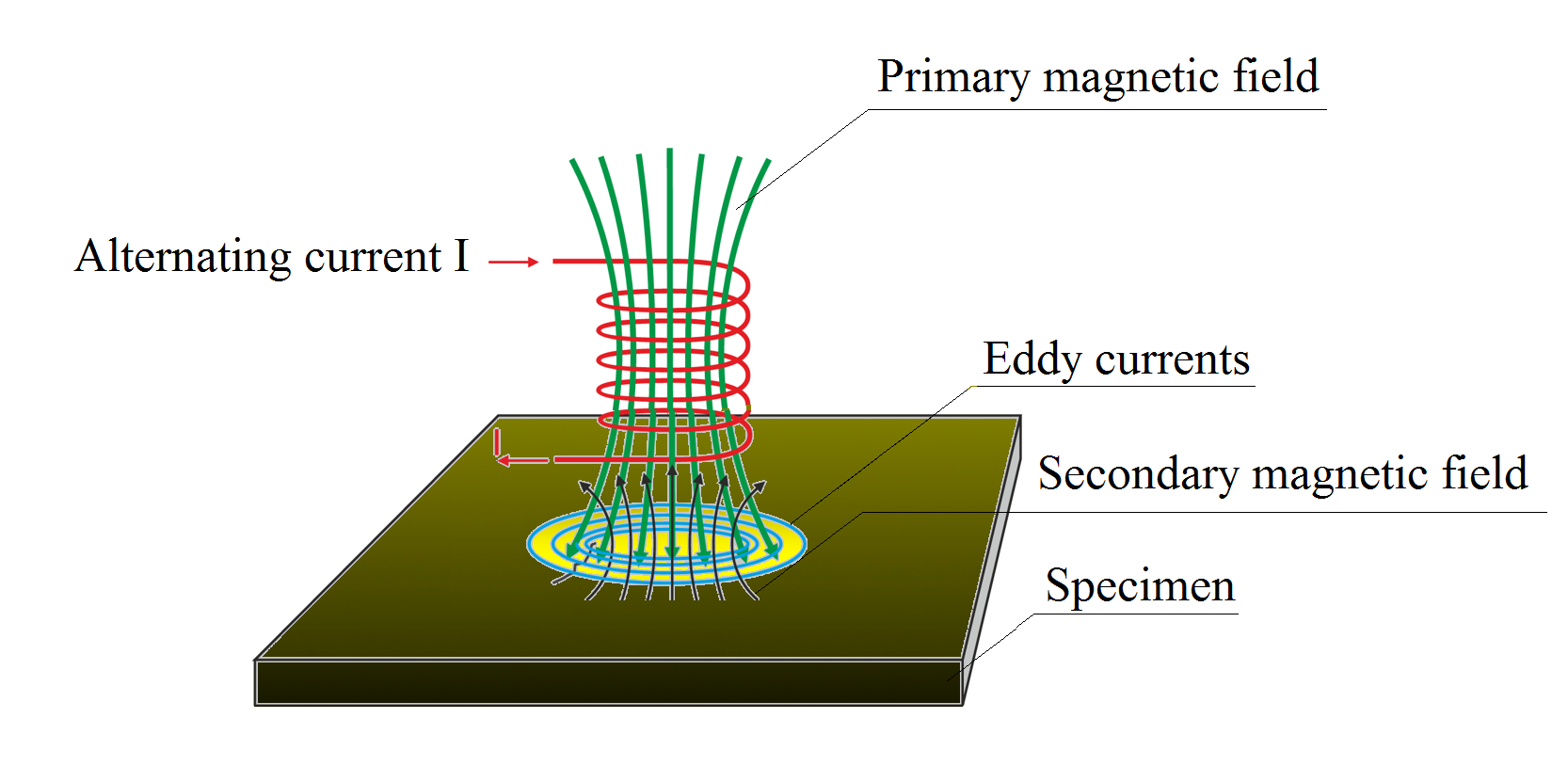

Principle of operation

The figure depicts a version of an attachable eddy-current transducer. It consists of a single coil shaped as a ring or curl. In the sensor coil, an alternate voltage source induces alternate current that creates primary alternating magnetic field. The coil created field partially penetrates the tested object to a certain depth, while the alternating magnetic field creates eddy currents in the tested object. Eddy current distribution depends on the frequency of primary alternating field, magnetic permeability of material, specific electrical resistance in material, and also on the tested object geometry in the area where the sensor is placed.

Where defects exist in the region of eddy current flows, it modifies their trajectories. This modifies the secondary field defined by eddy currents. Analyzing the shape, amplitude, and phase of secondary field of eddy currents, one can conclude whether defects exist or not. In addition to defects, the clearance and tested object thickness affect the distribution of the secondary field of eddy currents. Therefore, the method enables not only defect detection, but also the measurement of tested object thickness.

Pulsed eddy current test

The method of pulsed eddy current testing has a similar principle of operation: sensor coil direct current creates magnetic field that penetrates the tested object and induces eddy currents within it. After the primary magnetic field is disabled, the analysis of current decay rate in the tested object allows evaluating whether defects exist or not and changes in the thickness of tested object metal. This technology underlies the operation of our pulsed eddy current flaw detector PE4332 capable of evaluating objects through an insulation layer of up to 30 centimeters.

Key benefits of the eddy current test technology

- Non-contact testing with a large operating clearance

- High performance of testing that can reach rates of meters per second

- When measuring object thickness, low sensitivity to the object’s shape, presence of corrosion and rust