Description

The magnetic test method relies on the analysis of stray fields that emerge in the course of tested object magnetization in defect areas. The method enables high-performance express diagnostics of the condition of ferromagnetic tested objects. The method is used in the diagnostics of pipes with narrow and wide diameters, particularly in magnetic swabs for main pipe tests. It is used for testing vertical steel tanks, in industrial rod and rolled sheet tests. This is a non-contact method, and it requires no surface preparation.

Method’s principle of operation

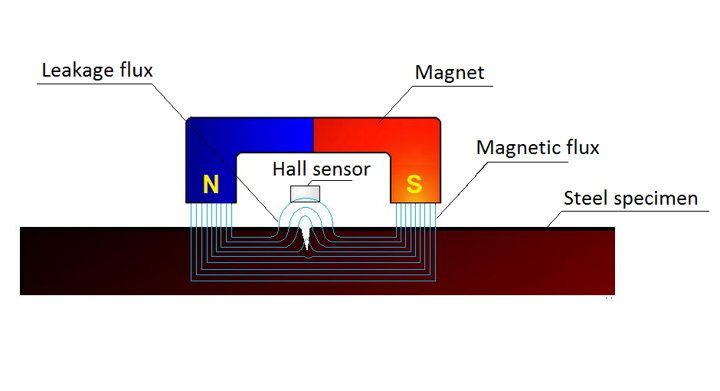

Please refer to the figure for the method’s principle of operation. The magnetic field source, with its function performed by a permanent magnet, creates a magnetic flux in the tested object. Should there be no defects, magnetic field appears inside the tested ferromagnetic object almost entirely, and the magnetic field sensor, it is depicted as a Hall sensor in the figure, detects the absence of magnetic field. Where there is a defect, the magnetic properties of the tested object change locally, and the magnetic field that strives to bypass the area of low magnetic permeability, surfaces partially and creates stray fields in the process. These fields are detected by the magnetic field sensor. Thus, data of magnetic field in the area where the sensor is located indicate the presence of a defect thereunder.

Key benefits of the magnetic test method

- No need for surface preparation of the tested object as this is a non-contact method

- High performance of testing: for example, main gas pipe tests show the productivity of up to 10 running meters per second

- High reliability of express testing

Diagnostic equipment by Oktanta

The magnetic test method underlies our portable drill pipe rapid testing diagnostic system PipeScope 60-170 designed for field detection of various defects such as: penetration defects, lateral defects in drill pipe walls, and also defects associated with changes in pipe wall thickness in the context of internal and external general corrosion.